At US Aggregates, geology plays a crucial role in identifying the unique characteristics of various rock layers. Whether our products are destined for road construction, building projects or specialized fillers and additives, the specific requirements of each of our customers applications dictate the quality standards and compositions our rocks and products must meet.

US Aggregates Geologist Zach Hoyes is at the forefront of this process. He received his bachelor’s degree in Geology from Indiana University Indianapolis (formerly IUPUI) and started working at US Aggregates in August of 2022. Zach has always been interested in the Earth’s history and studying what the Earth looked like before humans came along. “It’s interesting how wildly different things can be after Earth transformations and the insight you can get by looking at rocks and their formations,” Zach shared.

Zach’s daily routine involves assisting the mobile drill crew when they drill across our various sites and pulling samples from the ground. He logs the sample reports based on physical properties like color, density and composition and oversees testing the samples through physical or chemical tests depending on the site’s location.

Once testing is complete, Zach logs the results in a formalized format that breaks down the various rock types and formations. This information is shared with the engineering team for forecasting purposes.

X-Ray Fluorescence Rock Testing

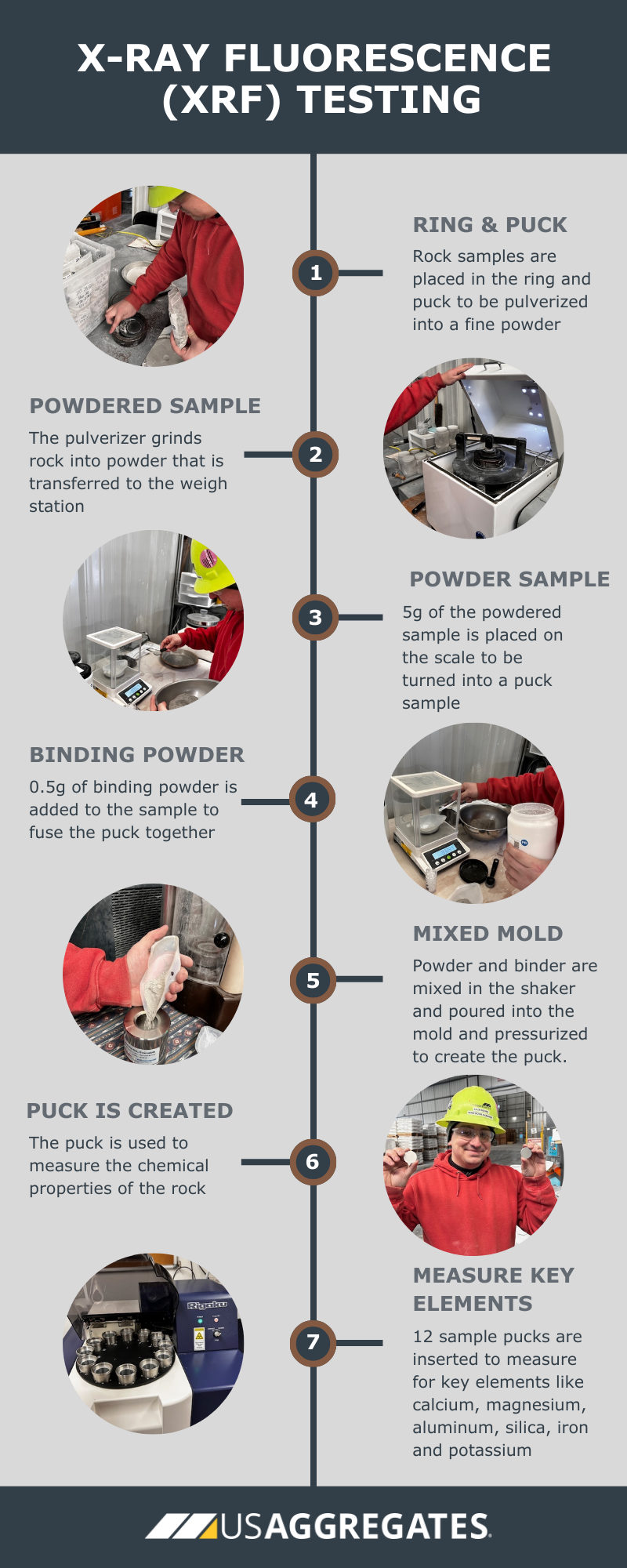

Our geology and quality control teams utilize X-Ray Fluorescence (XRF) testing daily to determine the specific chemical composition of our rock samples. We use this type of testing at our Portland fine grind location and Midwest Calcium Carbonates (MCC) as our customers in those industries have specific chemical requirements for products depending on their use case. An XRF Machine takes the following steps to determine what elemental concentrations are in rocks:

1. Rock samples are placed in the ring and puck to be pulverized into a fine powder

2. The pulverizer grinds rock into powder that is transferred to the weigh station

3. 5g of the powdered sample is placed on the scale to be turned into a puck sample

4. 0.5g of binding powder is added to the sample to fuse the puck together

5. The powder and binder are mixed in the shaker and poured into the mold and pressurized to create the puck

6. The puck is used to measure the chemical properties of the rock

7. 12 sample pucks are inserted simultaneously into the XRF machine to measure for key elements like calcium, magnesium, aluminum, silica, iron and potassium

LEAN Leader Core Shed Project

Zach has also been working on core sample reorganization in the core shed. This is part of his LEAN leader project to improve overall access and storage capacity for the core shed.

LEAN Leader is a training methodology to help train leaders in how they can utilize and implement the teachings from Lean and Six Sigma in their day-to-day operations outside of a classroom setting. Lean Leader achieves this by focusing on training for waste elimination, continuous improvement, process streamlining and maintaining efficiency with a customer-focused mindset. This ensures that every decision made is to the benefit of both the customer and US Aggregate employees.

He is reconfiguring everything in the shed so that it will be capable of handling future projects as we continue to grow. This renovation also makes room for alternative uses of surplus, older samples including testing for other organizations or material for geology classes.

Stay tuned for future geology project updates as Zach works to finalize the core shed and revitalize US Aggregates core sample storage methods. Thank you, Zach, for all of your expertise and creativity in the geology department!