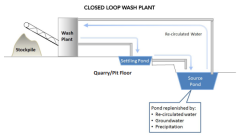

The water management system at the US Aggregates® Swisher sand and gravel plant in West Lafayette, Indiana, is built around the closed-loop recycling concept.

Figure 1. Example of Water Recycling for Aggregate Washing, Ontario Stone, Sand and Gravel Association (OSSGA).

Each year, Swisher pumps about 240 million gallons of water from both lakes on the property. We have implemented systems on-site to efficiently reuse and recycle all of it. Because all the pumped water is reused, the plant does not require a National Pollutant Discharge Elimination System (NPDES) discharge permit and, therefore, does not impact the aquatic ecosystem of the Wabash River in Tippecanoe County or any tributaries leading to it. By avoiding any discharge into these water bodies, the plant has minimized its environmental footprint and upheld its responsibility to preserve the natural habitats in the community. The implementation of this system enables US Aggregates to further streamline operational processes.

The benefits of our water reuse system extend beyond environmental compliance. The recycled water is integrated into various aspects of our operations, including material processing and washing, plant equipment dust control and water truck use to suppress fugitive dust in the customer stockyard and plant entrance.

Environmental Manager Laurie Webb says that because Swisher is a sand and gravel plant, the material inherently has a higher moisture content than limestone. “High truck traffic and periods of drought can still lead to dusty conditions, so we use the water resources we have on-site to suppress the dry areas,” Laurie emphasized. “We have an abundance of water on-site, and we have a water truck on the ready line, so it was an obvious choice to create a more sustainable solution to our water management.”

In addition to water reuse initiatives, the plant also uses monitoring wells throughout the property to track the static water levels of the groundwater onsite. This proactive approach to water management maintains a wholistic understanding of our water resources and assists in identifying potential water quantity issues early on. This knowledge is vital to the successful ongoing partnership between US Aggregates and the DNR’s Prophetstown State Park. By closely monitoring the groundwater levels, strategies can be developed to prevent future water quantity challenges that could impact the future growth of the state park.