The Evolution Continues: Exciting Updates to the Safety Rewards Program

Monday, August 26th, 2024

US Aggregates’ Safety Rewards Program is one of the many ways in which our company promotes a safety-first working environment. We offer employees the opportunity to earn additional incentives by taking part in safety training, emergency action drills and coaching coworkers. For a location to receive an incentive they must successfully reach 1,000 points across the year. Points are awarded based on how much of an influence entries have on safety and the overall quality of documentation.

Each of our locations can participate in our safety rewards program. A leader of safety earns the title of safety champion at each location. This person maintains at least 250 points each quarter and is involved in one EAD annually.

Safety and Health Representative, Shayla Meinders, shares Emergency Action Drills are one of the most beneficial attributes of the Safety Rewards Program. She believes the sites have been doing a great job this year planning and focusing on various scenarios such as first-aid incidents, fire drills and tire explosion simulations. Shayla emphasized, “We also encourage getting local EMS or First Responders involved in these drills.”

In 2024, our safety team has enhanced the safety program by implementing a few new changes including a new category, 5S. Part of Lean Six Sigma, 5S defines five pillars to generate a productive work environment through organization and cleaning. For example, a location may choose to weld a tool rack so that tools have a consistent place to be housed and to remove safety threats when tools could get in the way of work. The program also added scheduled Emergency Action Drills each month across plant locations. To encourage engagement with specific important safety themes, 25 additional points are given to all submissions related to the safety topics of the month and are meant to offer the opportunity for extra points. Safety topics of the month cover common topics like hearing conservation, tire safety and fire drills.

These adjustments help US Aggregates to continue to develop a strong safety culture and give different locations ample opportunity to secure safety points. Checkout four noteworthy submissions that have recently been received:

- Base Jumper Conveyor Installation – Delphi: This project significantly enhances crew safety and productivity by reducing the frequency of cleaning required for the base chute, leading to a more efficient work environment.

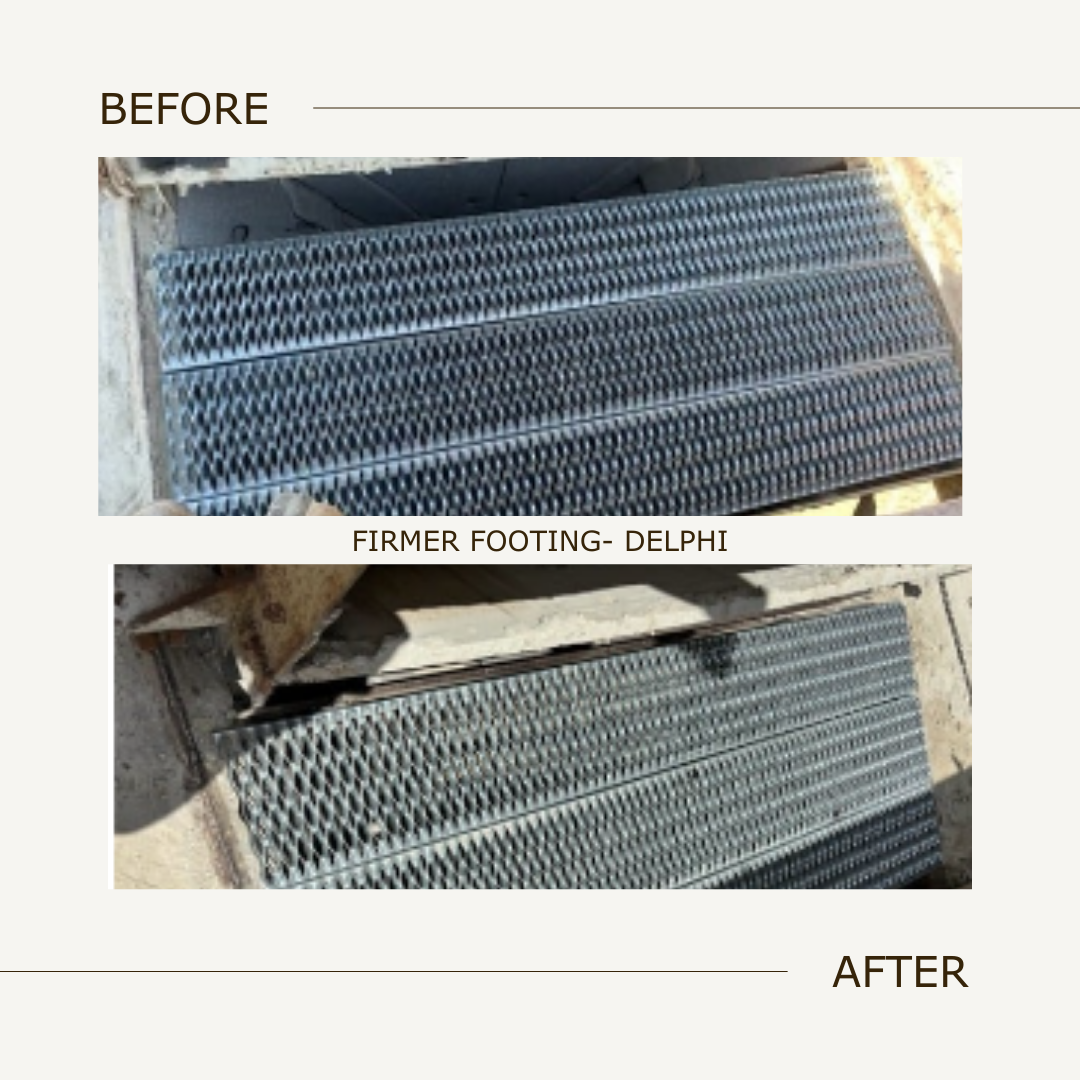

- Firmer Footing – Linn Grove: This initiative improved safety in the work area by replacing wooden planks with heavy-duty grip struts, ensuring better stability and reducing the risk of slips and falls.

- Yellow and Red Caution Tape Procedures – Monon: The team implemented a standardized system for using different colors of caution tape to clearly indicate hazards, facilitate injury prevention, and streamline scheduling for necessary repairs.

- Updated Visitor Sign-In and Sign-Out Procedures – Columbus: With the help of MSHA, the team developed a new sign-in and sign-out sheet to enhance safety measures for all site visitors. It includes questions about the purpose of the visit, verification of essential personal protective equipment (PPE) and confirmation of training completion.

Written By: Anthony Treadaway